The LS3 crate engine and Tremec Magnum gearbox has arrived.

Slight problems to resolve.

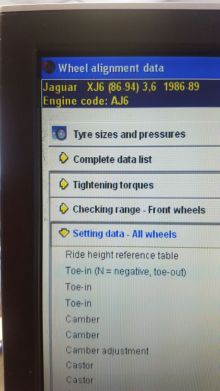

The yoke I had acquired was a 27 spline yoke from the tremec t56 unfortunately it does not fit the magnum gearbox.

The Yoke needed for a magnum transmission is 31 spline as detailed.

Dana Spicer 3-3-5961X

1350 Series Slip Yoke 31 Spline fits Tremec T56 MAGNUM and TKO 600 Transmission

Length to center of u-joint… Dimension #1 = 6 1/2 inches

Barrel Diameter… Dimension #2 = 1 11/16 inches

Barrel Length… Dimension #3 = 4 1/2 inches

U-joint cap diameter… Dimension #4 = 1 3/16 inches

U-joint width… Dimension #5 = 3 5/8 inches

Series… 1350

Spline count… 31

Good news – called GD and sounds like they have one in stock. Ill order up a full propshaft from GD as soon as I do a trial fit of the engine.

Tried the engine and transmission in for size and works out the prop gap is about 366mm I guess the actual prop length will be something a little shorter than this with an allowance for a bit of clearance on the sliding spline.

Clutch Trial Fit

What on earth was I doing a clutch trial fit for you may well ask, well the truth is I wasn’t meant to but after fitting the clutch and pressure plate housing I started to do a bit of reading up to find out what the odd looking connection was on the slave cylinder. Whilst searching for information on the slave cylinder fluid input fitting which turns out to be “Quick Disconnect Fitting” I also discovered that I had inserted the pilot bearing the wrong way around. It said nothing on the instructions I received with the installation kit about direction for the pilot bearing and although I did notice it had a slight difference I chose to put it in with the needle bearings visible and closest to the transmission. My logic was simply to get the needle bearings further along the shaft end.

Turns out my logic was wrong and the bearing goes in with the closed end towards the tranny, obvious when you realise that this is the grease seal end. OK so the clutch has to come back off – no big deal but how the heck will I get the pilot bearing out that i just drifted in with a 3lb hammer? My first thought was, OK its just going to get butchered out and buy a new pilot bearing but a quick google check and low and behold some genius on youtube had figured out a 3 minute solution. All I had to do was pack the centre of the bearing with grease and insert a close fit (15mm) drift through the centre of the bearing, strike it with a hammer a few times and low and behold the bearing jumps out. Extreme Hydraulic pressure pushes it out from behind – what a good trick – and it works – youtube to my rescue!

Now on to the problem of that Quick Disconnect which got me searching in the first place. Apparently these fittings are used quite extensively in the USA and the idea is to enable disconnection of the slave cylinder for removal of transmission during clutch service etc. without introducing air into the system so alleviating the need to bleed.

The Quick Disconnect is the big orange part in the picture. The other opening is for the bleed nipple which is lengthy so it can just be bled from the bellhousing opening. I’m going to fit external bleed flexi pipes so I plan to modify both of these fittings. Pretty easy on the bleed side since its just an m10 fitting, so a standard male end of a flexi would work here but the quick disconnect is not so simple since its fitted into the slave cylinder aluminium casing with a flat o ring and groove, held in place with a roll pin. I think the simplest method here may be to cut this orange bit off and have the blank pipe end threaded to m10 with a taper. That way I could fit an m10 female/female extension fitting, effectively replacing the orange part with this.

I’ll figure this out over the next couple of days and report my solution here.

Trial fit to get prop length

Things are starting to get heavy LS3 and Tremec Magnum in place.

Engine back out to sort the clutch slave issue here’s a pic of the new fittings. The banjo fitting on top is for the remote bleed flexi this replaces the long brass bleed screw (above). The setup on the lower input shows the new fitting that replaces the ‘quick disconnect’ (orange plug above). It was easier to turn this fitting with a standard male metric brake end as shown, but since I already had my flexi pipe with a male end just adding a standard female/female coupling in between joins it all together.

With this complete I can re-install the engine and gearbox in the chassis.